As IndiGo emerged on top of the Indian aviation market, overcoming the test of competition by virtue of its size, there is a lot to learn from the cost management strategies they adopted. While the aviation market is characterized by huge losses, IndiGo has managed to remain profitable by following a very simple business approach. The blog attempts to identify the key success factor that helped IndiGo gain leverage in the market.

The Power of a Low-Cost, No-Frills Business Model

IndiGo was founded with a clear philosophy of being a low-cost carrier. This philosophy was based on efficiency rather than indulgence. IndiGo decided not to go for high-cost indulgences like providing meals and entertainment during the flight. Instead, the focus was on serving the middle class of India, which was growing rapidly. IndiGo kept things simple so that costs did not increase. Also, the pricing strategy of IndiGo helped generate high traffic, and this helped increase profitability by distributing fixed costs. IndiGo also chose to focus on generating revenue from additional sales like seat selection and food and beverage sales. This helped IndiGo stick to high profitability even during a price war. IndiGo’s focus on being a no-frills airline was not about delivering low value to customers but about sticking to the business while being profitable was of utmost importance.

Fleet Standardization and Smart Aircraft Strategy

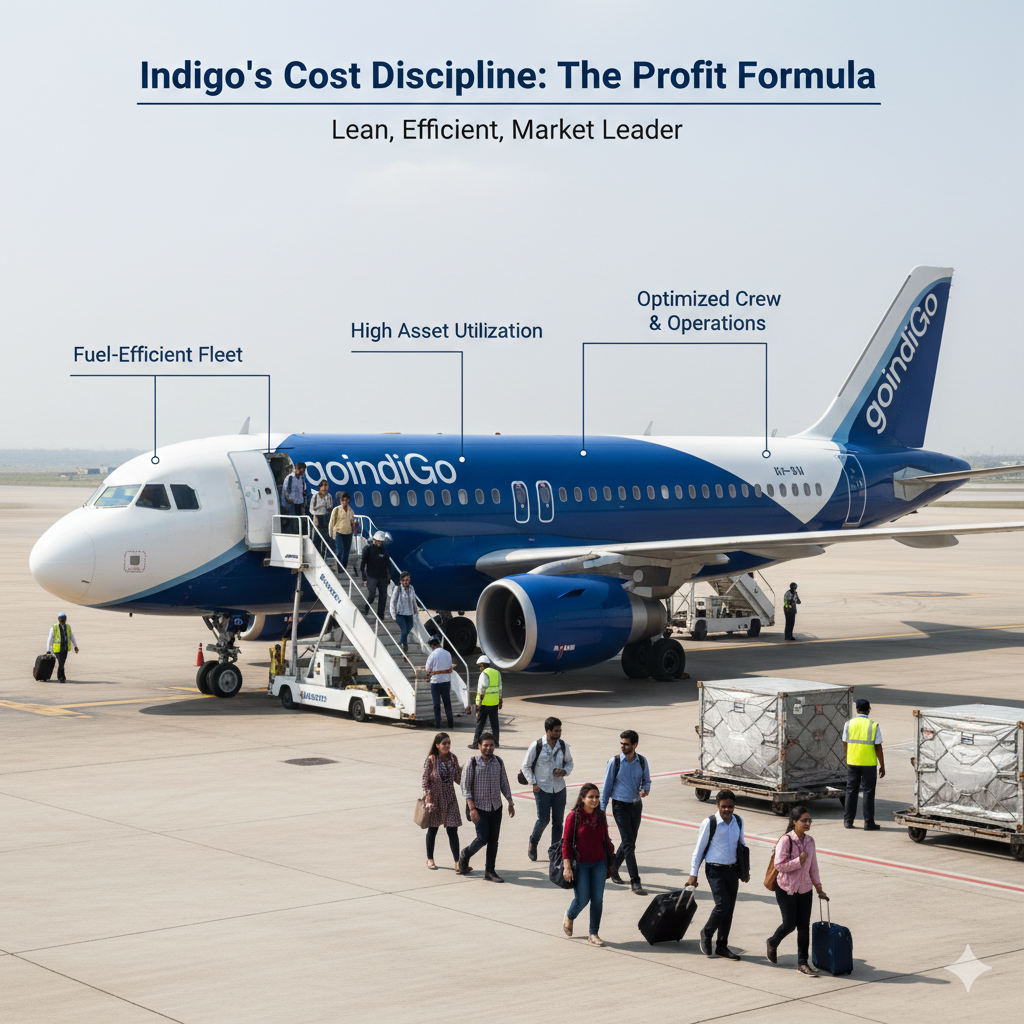

IndiGo’s decision to build a fleet of aircraft from the same manufacturer (specifically Airbus A320 family). Using aircraft from the same source has allowed IndiGo to train pilots on fewer types of planes, allow cabin crew to work with new aircraft without having to learn everything from scratch, streamline maintenance processes, and minimize the amount of spare parts IndiGo has to keep in stock.

The aircraft’s similarity has resulted in a decrease in operational errors, and downtime, predictability of maintenance costs, and the ability to purchase aircraft in bulk has allowed IndiGo to negotiate lower prices from the manufacturers and to be able to schedule delivery of new aircraft at times that are convenient for them (as opposed to having to take the manufacturer’s schedule).

By using the most efficient aircraft available to them, IndiGo has not only reduced the cost of guage (fuel) to operate their aircraft, but also has reduced their environmental impact by using aircraft that will continue to reduce fuel consumption as long they remain operational. In short, standardizing the type of aircraft used by IndiGo has created greater flexibility among their crews, leading to improved aircraft utilization and the potential for increased profitability due to cost differentials amongst airlines. Finally, as IndiGo strives to operate a low-cost carrier, this standardization of the aircraft fleet creates opportunities to generate cost savings for the future while continuing to provide reliable and scalable operations.

Operational Excellence and On-Time Performance

IndiGo is well-known for being punctual and has a good reputation for this. Punctuality is a core part of our strategy of controlling costs. To make sure we are able to get aircraft back into service quickly, IndiGo has processes that are extremely consistent and standardized and enable us to turn around aircraft quickly, as well as run efficient ground operations. By turning around aircraft quickly, they are able to fly longer hours and therefore generate more revenue for the company instead of having aircraft idle at airports. Consistent on-time performance allows us to reduce costs related to delays such as compensation, rescheduling and crew overtime. In addition, a reliable operation builds trust with customers and encourages repeat business and reduces the need for extensive promotional spending. IndiGo provides for operational stability through training of staff and clear communication protocols to minimize operational disruptions and facilitate smooth coordination between departments. Thus, the disciplined approach to operations, enabled IndiGo to recover schedules in a timely manner even during inclement weather or congested airport situations. Overall, by employing operational efficiency as a method of controlling costs, IndiGo was able to combine customer satisfaction, reduced costs and increased profitability.

Cost Control Culture and Data-Driven Decision Making

IndiGo has been able to implement an ingrained cost-conscious culture throughout the organization, beyond just its strategic or operational view, leading to IndiGo’s overall success. Cost Optimization is the main focus of all departments across the organization, regardless of whether they are in cargo, flight operations, or purchasing, without losing focus on creating a safe and reliable operation. IndiGo uses advanced analytical tools and performance data to measure its fuel efficiency, route profitability, and operational efficiencies on a real-time basis. Data is leveraged to enable management to make quick evidence-based decisions regarding pricing, scheduling, and capacity planning. The strength of vendor negotiations and longstanding strategic supplier relationships ensure IndiGo has competitive fuel, airport services and maintenance pricing. When there are industry events that disrupt normal operations for all airlines, such as fuel prices or global emergency events, IndiGo has been able to react more quickly than many competitors because of this disciplined approach. All Employees have been encouraged to explore creative ways to optimize costs and improve processes to create a companywide efficient culture. Through data analysis and cultural alignment, the focus on cost control is maintained as a continuous process, rather than as a reactive measure.

Conclusion

“The story of IndiGo’s journey to becoming the most profitable airline in India is a story of discipline, not luxury, and that is what the aviation industry is all about. For IndiGo, as a low-cost airline true to its philosophy, to achieve airline operations that can endure the turbulent industry, the key was to standardize its fleet, to achieve operational excellence, and to inculcate the culture of cost consciousness.” IndiGo was able to succeed in the industry where others struggled to survive by making efficiency its strength, and that the key to sustainable profitability lies in doing the basics “every single day.”